- Overview

- Inquiry

- Related Products

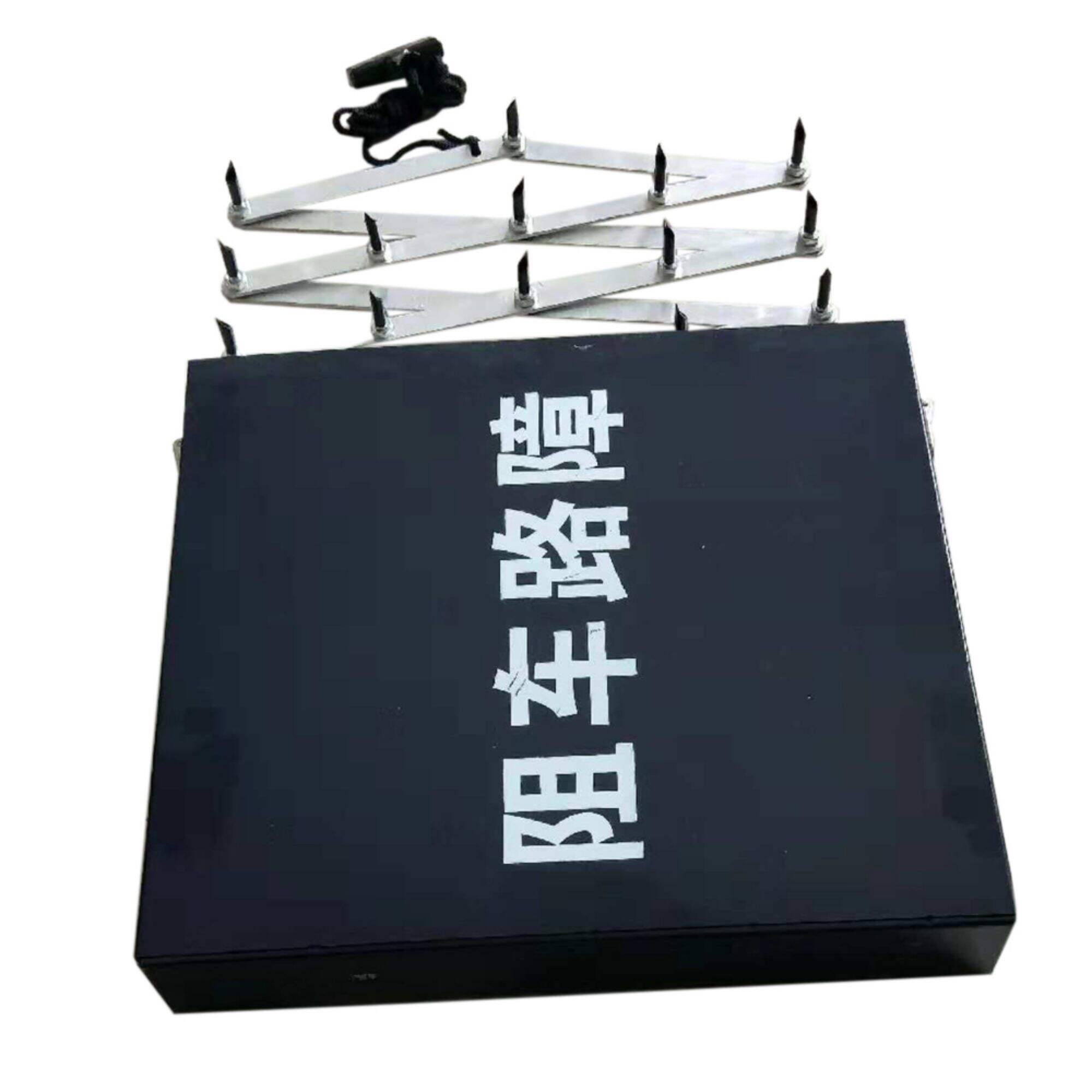

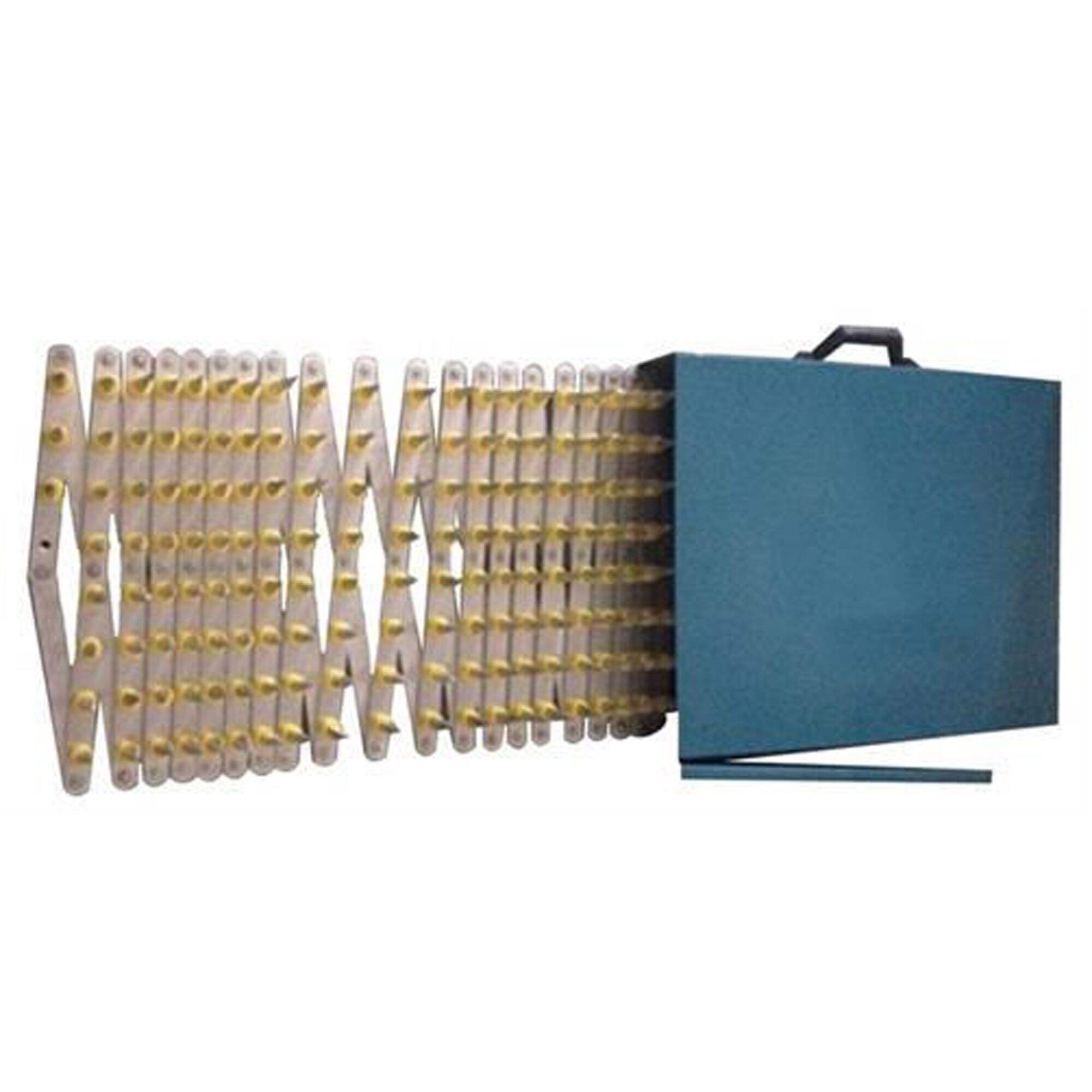

The Puncture Deflation Roadblock (L) Spike Strips feature an extendable frame constructed from aluminum alloy profiles. The telescopic length can be freely pulled out, and the frame is equipped with 158 sharp triangular needles. The edges of the needles have exhaust grooves, and when a vehicle's wheels pass over the roadblock, the needles penetrate the tires, causing immediate deflation and rendering the vehicle immobile. The manual obstruction roadblock complies with the relevant standards of GAT421-2003 Puncture Deflation Roadblock.

Specifications

Product Name Puncture Deflation Roadblock Spike Strips

The structure Consists of a metal base and triangular metal needles.

Effective Length of Roadblock 8m

Needle Length 48. 0mm

Effective Spacing of Needles 53mm

Dimensions 550430100 (LengthWidthHeight)

Number of Needles 158

Weight ≤13 KG

Markings The product surface is labeled with Police, Obstruction Roadblock, and other relevant markings. Customization is available for bulk orders.

Key Features

The extendable frame, made of durable aluminum alloy, allows for flexible deployment and quick immobilization of vehicles.

The 158 sharp triangular needles, equipped with exhaust grooves, efficiently deflate tires upon contact.

Compliance with the standards of GAT421-2003 Puncture Deflation Roadblock ensures quality and reliability.

The product is marked with Police and Obstruction Roadblock for clear identification.

Customizable markings for bulk orders to meet specific requirements.

Usage Guidelines

Ensure the roadblock is placed in the intended deployment area, with the Police side facing outward.

Extend the frame to the desired length manually, ensuring proper alignment with the road.

The roadblock is effective in puncturing and deflating tires, rendering the vehicle immobile for security purposes.

Store in a secure and dry location when not in use to prolong the product's lifespan.

Safety Measures

Use the roadblock in accordance with local laws and regulations.

Keep bystanders at a safe distance during deployment to prevent accidental injury.

Regularly inspect the roadblock for any signs of wear or damage, and perform maintenance as needed.

Ensure proper training for individuals responsible for deploying and using the roadblock.

In case of malfunction or damage, contact the manufacturer or authorized service provider for assistance.

En

En

CN

CN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH